Application case analysis of high strength steel in steel structure of super high-rise building

Table of Contents

Benefits of Using High Strength Steel in Super High-Rise Building Structures

High strength steel has become increasingly popular in the construction industry, particularly in the steel structures of super high-rise buildings. This material offers a range of benefits that make it an attractive choice for architects and engineers looking to create tall, durable, and safe structures. In this article, we will explore the application case analysis of high strength steel in the steel structure of super high-rise buildings.

One of the key benefits of using high strength steel in super high-rise building structures is its superior strength-to-weight ratio. High strength steel is able to support heavy loads while being lighter than traditional steel, allowing for taller and more slender building designs. This can result in cost savings on materials and construction, as well as increased flexibility in architectural design.

Additionally, high strength steel offers improved seismic performance compared to traditional steel. Super high-rise buildings are often located in earthquake-prone regions, making it essential to use materials that can withstand strong lateral forces. High strength steel has greater ductility and toughness, allowing it to deform without fracturing during an earthquake and dissipate energy more effectively, reducing the risk of structural failure.

Furthermore, high strength steel is highly resistant to corrosion, which is a critical factor in the longevity and durability of super high-rise building structures. Corrosion can weaken steel structures over time, leading to maintenance issues and safety concerns. By using high strength steel, architects and engineers can ensure that their buildings will remain structurally sound for decades to come, reducing the need for costly repairs and maintenance.

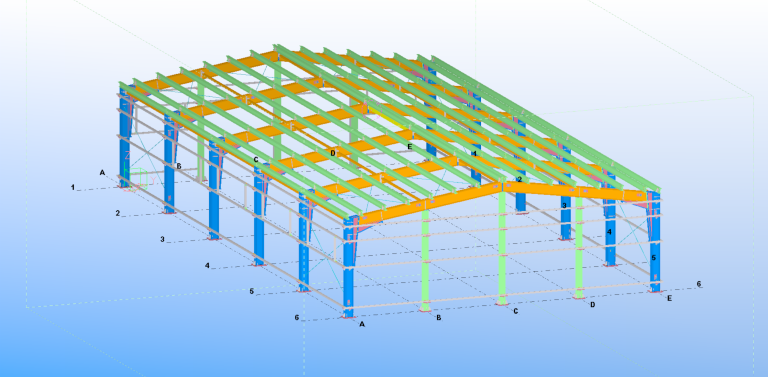

In a recent application case analysis, a super high-rise building in a coastal city was constructed using high strength steel in its steel structure. The building was designed to withstand strong winds, saltwater exposure, and seismic activity, making high strength steel the ideal choice for this project. The use of high strength steel allowed the building to achieve its desired height and architectural design while ensuring structural integrity and safety.

During construction, the high strength steel beams and columns were easily transported and assembled, thanks to their lighter weight and higher strength. This resulted in faster construction times and reduced labor costs, making the project more efficient and cost-effective. Additionally, the superior seismic performance of high strength steel provided peace of mind to both the developers and future occupants of the building.

In conclusion, the application case analysis of high strength steel in the steel structure of super high-rise buildings demonstrates the numerous benefits of using this material in construction. From its superior strength-to-weight ratio and seismic performance to its resistance to corrosion and ease of construction, high strength steel offers a range of advantages that make it an ideal choice for tall, durable, and safe buildings. Architects and engineers looking to create innovative and resilient structures should consider incorporating high strength steel into their designs for optimal results.

Challenges and Considerations in Applying High Strength Steel in Super High-Rise Building Construction

High strength steel has become increasingly popular in the construction of super high-rise buildings due to its superior strength-to-weight ratio and ability to withstand high loads. However, the application of high strength steel in such structures comes with its own set of challenges and considerations that need to be carefully addressed.

One of the main challenges in using high strength steel in super high-rise buildings is the need for specialized welding techniques. High strength steel has a higher carbon content than traditional steel, which can make it more susceptible to cracking during the welding process. This requires the use of preheating and post-weld heat treatment to prevent the formation of brittle welds and ensure the structural integrity of the building.

Another consideration when using high strength steel in super high-rise buildings is the potential for hydrogen embrittlement. Hydrogen embrittlement occurs when hydrogen atoms diffuse into the steel, causing it to become brittle and prone to cracking under stress. This can be a significant concern in high strength steel structures, as the high levels of stress and load-bearing requirements can exacerbate the effects of hydrogen embrittlement.

In addition to welding and hydrogen embrittlement, the design and fabrication of high strength steel structures in super high-rise buildings must also take into account the potential for buckling and instability. High strength steel has a lower modulus of elasticity than traditional steel, which can lead to increased deflection and deformation under load. This can result in structural instability and compromise the safety of the building.

To address these challenges and considerations, engineers and architects must carefully design and analyze the use of high strength steel in super high-rise buildings. This includes conducting thorough structural analysis and testing to ensure the integrity and safety of the building, as well as implementing quality control measures during fabrication and construction.

Despite the challenges and considerations associated with using high strength steel in super high-rise buildings, the benefits of this material cannot be overlooked. High strength steel offers a significant reduction in material weight, which can lead to cost savings and improved efficiency in construction. Additionally, the superior strength and durability of high strength steel can result in longer-lasting and more resilient structures that are better equipped to withstand the demands of a super high-rise building.

In conclusion, the application of high strength steel in the construction of super high-rise buildings presents both challenges and considerations that must be carefully addressed. From specialized welding techniques to the risk of hydrogen embrittlement and structural instability, engineers and architects must take a comprehensive approach to design and construction to ensure the safety and integrity of the building. By carefully analyzing and addressing these challenges, high strength steel can be successfully integrated into super high-rise buildings, offering a durable and efficient solution for modern construction projects.