Application prospect of intelligent logistics system in transportation and storage of steel structure components.

Inhoudsopgave

Benefits of Implementing Intelligent Logistics Systems in Steel Structure Component Transportation

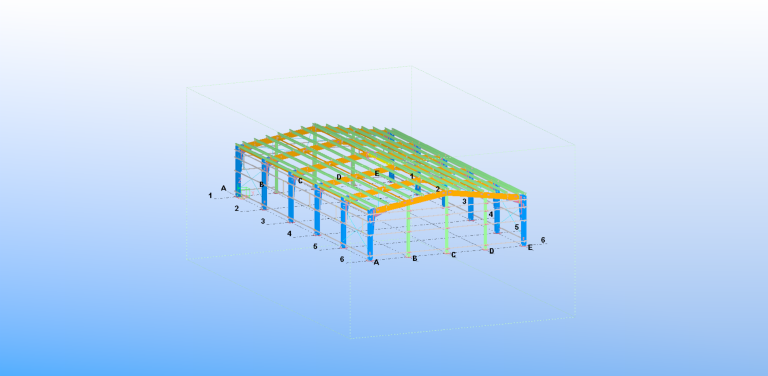

Steel structures are a crucial component in the construction industry, providing strength and durability to buildings and infrastructure projects. The transportation and storage of steel structure components play a vital role in ensuring the timely and efficient completion of construction projects. With the advancement of technology, intelligent logistics systems have emerged as a game-changer in the transportation and storage of steel structure components.

One of the key benefits of implementing intelligent logistics systems in the transportation and storage of steel structure components is the optimization of the supply chain. By utilizing advanced technologies such as RFID tags, GPS tracking, and real-time monitoring systems, companies can track the movement of steel components from the manufacturing facility to the construction site. This real-time visibility allows for better coordination and planning, leading to improved efficiency and reduced lead times.

In addition to optimizing the supply chain, intelligent logistics systems also enhance the safety and security of steel structure components during transportation and storage. With features such as temperature and humidity sensors, companies can monitor the environmental conditions of the storage facilities to prevent corrosion and damage to the steel components. Furthermore, the use of GPS tracking and geofencing technology enables companies to track the location of steel components in transit, reducing the risk of theft and unauthorized access.

Another significant benefit of implementing intelligent logistics systems in the transportation and storage of steel structure components is the reduction of operational costs. By automating processes such as inventory management, route optimization, and scheduling, companies can minimize manual labor and streamline operations. This not only leads to cost savings but also improves overall productivity and efficiency.

Furthermore, intelligent logistics systems enable companies to make data-driven decisions based on real-time information. By analyzing key performance indicators such as delivery times, inventory levels, and transportation costs, companies can identify areas for improvement and implement strategies to optimize their logistics operations. This data-driven approach allows companies to adapt to changing market conditions and customer demands, ensuring a competitive edge in the industry.

Moreover, intelligent logistics systems facilitate seamless communication and collaboration between stakeholders involved in the transportation and storage of steel structure components. By providing a centralized platform for sharing information and coordinating activities, companies can improve communication, reduce errors, and enhance overall visibility across the supply chain. This collaborative approach fosters stronger relationships with suppliers, manufacturers, and customers, leading to improved customer satisfaction and loyalty.

In conclusion, the application prospect of intelligent logistics systems in the transportation and storage of steel structure components is promising. By optimizing the supply chain, enhancing safety and security, reducing operational costs, and enabling data-driven decision-making, companies can achieve greater efficiency, productivity, and competitiveness in the construction industry. As technology continues to advance, intelligent logistics systems will play an increasingly important role in shaping the future of steel structure component transportation and storage.

Challenges and Solutions for Integrating Intelligent Logistics Systems in Steel Structure Component Storage

Steel structure components are essential building materials used in various construction projects, ranging from industrial facilities to residential buildings. The transportation and storage of these components play a crucial role in ensuring the efficiency and safety of construction processes. With the advancement of technology, intelligent logistics systems have emerged as a promising solution to streamline the transportation and storage of steel structure components. In this article, we will explore the application prospect of intelligent logistics systems in the transportation and storage of steel structure components, as well as the challenges and solutions for integrating these systems into existing processes.

Intelligent logistics systems leverage cutting-edge technologies such as artificial intelligence, Internet of Things (IoT), and big data analytics to optimize the movement of goods within a supply chain. In the context of steel structure component transportation and storage, these systems can provide real-time tracking of inventory, automate material handling processes, and optimize storage space utilization. By integrating intelligent logistics systems into their operations, construction companies can improve efficiency, reduce costs, and enhance overall productivity.

One of the key benefits of intelligent logistics systems in the transportation and storage of steel structure components is real-time tracking and monitoring. With the help of IoT sensors and RFID tags, companies can track the location and condition of each component throughout the supply chain. This real-time visibility enables better inventory management, reduces the risk of lost or damaged components, and improves overall supply chain transparency. By leveraging data analytics, companies can also gain valuable insights into their operations, identify bottlenecks, and make data-driven decisions to optimize their processes.

Another advantage of intelligent logistics systems is the automation of material handling processes. Traditional methods of transporting and storing steel structure components often involve manual labor, which can be time-consuming and error-prone. By implementing automated material handling systems such as robotic arms, conveyor belts, and automated guided vehicles (AGVs), companies can streamline their operations, reduce labor costs, and improve overall efficiency. These systems can also enhance workplace safety by minimizing the risk of accidents and injuries associated with manual handling.

Furthermore, intelligent logistics systems can optimize storage space utilization in warehouses and construction sites. By using data analytics to analyze inventory levels, demand forecasts, and storage capacity, companies can optimize the layout of their storage facilities, reduce wasted space, and improve inventory turnover. Automated storage and retrieval systems (AS/RS) can also help companies maximize storage density and improve picking efficiency. By implementing these technologies, companies can reduce storage costs, increase operational efficiency, and enhance overall supply chain performance.

Despite the numerous benefits of intelligent logistics systems, there are several challenges that companies may face when integrating these systems into their operations. One of the main challenges is the high initial investment required to implement these technologies. Companies need to invest in hardware, software, and infrastructure to deploy intelligent logistics systems, which can be a significant financial burden. Additionally, companies may face resistance from employees who are accustomed to traditional methods of operation and may be reluctant to adopt new technologies.

To overcome these challenges, companies can take a phased approach to implementing intelligent logistics systems, starting with pilot projects to demonstrate the benefits of these technologies. Companies can also provide training and support to employees to help them adapt to the new systems and understand the value they bring to the organization. By taking a strategic and collaborative approach to implementation, companies can overcome the challenges of integrating intelligent logistics systems and unlock the full potential of these technologies in the transportation and storage of steel structure components.

In conclusion, intelligent logistics systems offer a promising solution to optimize the transportation and storage of steel structure components in construction projects. By leveraging cutting-edge technologies such as artificial intelligence, IoT, and data analytics, companies can improve efficiency, reduce costs, and enhance overall productivity. While there are challenges to integrating these systems into existing processes, companies can overcome these obstacles by taking a strategic and collaborative approach to implementation. By embracing intelligent logistics systems, companies can transform their operations and gain a competitive edge in the construction industry.