Intelligent manufacturing technology innovation of steel structure prefabricated components

Table of Contents

Benefits of Implementing Intelligent Manufacturing Technology in Steel Structure Prefabricated Components

Intelligent manufacturing technology has revolutionized the way steel structure prefabricated components are produced. This innovative approach combines advanced automation, artificial intelligence, and data analytics to streamline the manufacturing process and improve overall efficiency. By implementing intelligent manufacturing technology, companies in the steel structure industry can benefit from increased productivity, reduced costs, and improved quality control.

One of the key benefits of intelligent manufacturing technology is its ability to optimize production processes. By utilizing automation and robotics, manufacturers can significantly reduce the time and labor required to produce steel structure prefabricated components. This not only speeds up the production process but also allows for greater flexibility in meeting customer demands. With intelligent manufacturing technology, companies can easily adjust production schedules and scale up or down as needed, ensuring that they can meet tight deadlines and deliver high-quality products to their customers.

In addition to optimizing production processes, intelligent manufacturing technology also helps to reduce costs. By automating repetitive tasks and minimizing human error, manufacturers can lower their operating expenses and improve their bottom line. This cost savings can be passed on to customers, making steel structure prefabricated components more affordable and competitive in the market. Furthermore, intelligent manufacturing technology allows companies to better manage their resources, ensuring that they are used efficiently and effectively to maximize productivity and minimize waste.

Another significant benefit of implementing intelligent manufacturing technology is improved quality control. By utilizing sensors, data analytics, and machine learning algorithms, manufacturers can monitor and analyze every step of the production process in real-time. This allows them to quickly identify and address any issues or defects, ensuring that only high-quality products are delivered to customers. With intelligent manufacturing technology, companies can achieve greater consistency and precision in their production processes, leading to better overall product quality and customer satisfaction.

Furthermore, intelligent manufacturing technology enables companies to enhance their sustainability efforts. By optimizing production processes and reducing waste, manufacturers can minimize their environmental impact and operate more sustainably. This not only benefits the environment but also helps companies meet regulatory requirements and attract environmentally conscious customers. By implementing intelligent manufacturing technology, companies can demonstrate their commitment to sustainability and differentiate themselves in the market.

Overall, the benefits of implementing intelligent manufacturing technology in steel structure prefabricated components are clear. From optimizing production processes and reducing costs to improving quality control and enhancing sustainability efforts, intelligent manufacturing technology offers numerous advantages for companies in the steel structure industry. By embracing this innovative approach, manufacturers can stay ahead of the competition, meet customer demands, and drive growth and success in the rapidly evolving manufacturing landscape.

Future Trends and Innovations in Intelligent Manufacturing Technology for Steel Structure Prefabricated Components

In recent years, the construction industry has seen a significant shift towards the use of steel structure prefabricated components. This trend is driven by the numerous benefits that prefabricated components offer, including reduced construction time, improved quality control, and cost savings. As the demand for prefabricated components continues to grow, manufacturers are turning to intelligent manufacturing technology to further enhance the efficiency and quality of their products.

One of the key innovations in intelligent manufacturing technology for steel structure prefabricated components is the use of advanced robotics and automation. Robots are being used to perform a wide range of tasks, from cutting and welding steel beams to assembling complex structures. By automating these processes, manufacturers are able to increase production speed, improve accuracy, and reduce the risk of human error.

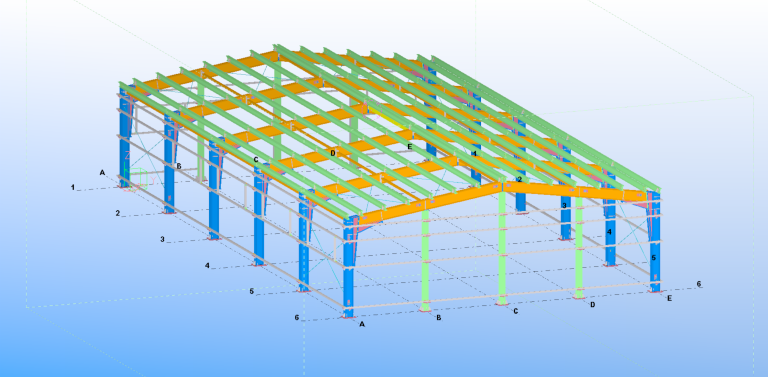

Another important innovation in intelligent manufacturing technology is the use of advanced software systems for design and planning. These systems allow manufacturers to create detailed 3D models of prefabricated components, which can then be used to optimize the manufacturing process and ensure that each component is produced to the highest standards. By using these software systems, manufacturers are able to reduce waste, minimize rework, and improve overall efficiency.

In addition to robotics and software systems, manufacturers are also exploring the use of artificial intelligence (AI) and machine learning in the production of steel structure prefabricated components. AI algorithms can be used to analyze data from sensors and cameras on the production line, allowing manufacturers to identify potential issues before they occur and make real-time adjustments to improve efficiency and quality. Machine learning algorithms can also be used to optimize production schedules, predict maintenance needs, and improve overall performance.

One of the key advantages of intelligent manufacturing technology is its ability to adapt to changing market demands and customer requirements. By using advanced sensors and data analytics, manufacturers can monitor production processes in real-time and make adjustments as needed to meet changing demand. This flexibility allows manufacturers to quickly respond to market trends and deliver customized products to their customers.

Looking ahead, the future of intelligent manufacturing technology for steel structure prefabricated components is bright. As technology continues to advance, manufacturers will have access to even more powerful tools and capabilities to improve their production processes. From advanced robotics and automation to AI and machine learning, the possibilities for innovation are endless.

In conclusion, intelligent manufacturing technology is revolutionizing the production of steel structure prefabricated components. By leveraging advanced robotics, software systems, and AI, manufacturers are able to improve efficiency, quality, and flexibility in their production processes. As the industry continues to evolve, we can expect to see even more exciting innovations that will further enhance the capabilities of prefabricated components and drive continued growth in the construction industry.