Circular economy practice of steel industry.

Table of Contents

Sustainable Steel Production Methods in Circular Economy

The steel industry is a vital component of the global economy, providing the raw materials necessary for the construction of buildings, infrastructure, and various consumer goods. However, the production of steel is also a resource-intensive process that can have significant environmental impacts. In recent years, there has been a growing recognition of the need to transition towards more sustainable practices in the steel industry, with a particular focus on the principles of the circular economy.

The circular economy is a concept that aims to minimize waste and maximize the value of resources by keeping products and materials in use for as long as possible. In the context of the steel industry, this means finding ways to recycle and reuse steel products and by-products, rather than simply disposing of them as waste. By adopting circular economy principles, steel producers can reduce their environmental footprint, conserve natural resources, and create new opportunities for innovation and growth.

One of the key strategies for implementing circular economy practices in the steel industry is the promotion of recycling and reuse. Steel is a highly recyclable material, with the ability to be melted down and reprocessed multiple times without losing its strength or quality. By collecting and recycling scrap steel from end-of-life products, manufacturing waste, and construction and demolition sites, steel producers can reduce their reliance on virgin raw materials and lower their energy consumption and greenhouse gas emissions.

In addition to recycling scrap steel, the steel industry is also exploring new ways to reuse by-products and waste materials generated during the production process. For example, steel slag, a by-product of the steelmaking process, can be used as a construction aggregate in road building and cement production. By finding new applications for these materials, steel producers can reduce the amount of waste sent to landfills and create value from what was once considered a by-product.

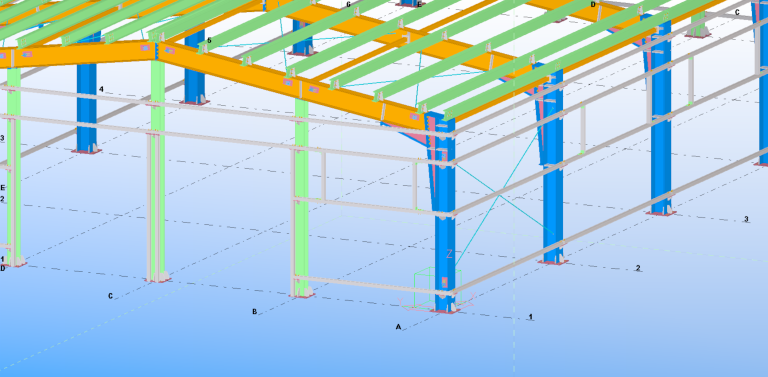

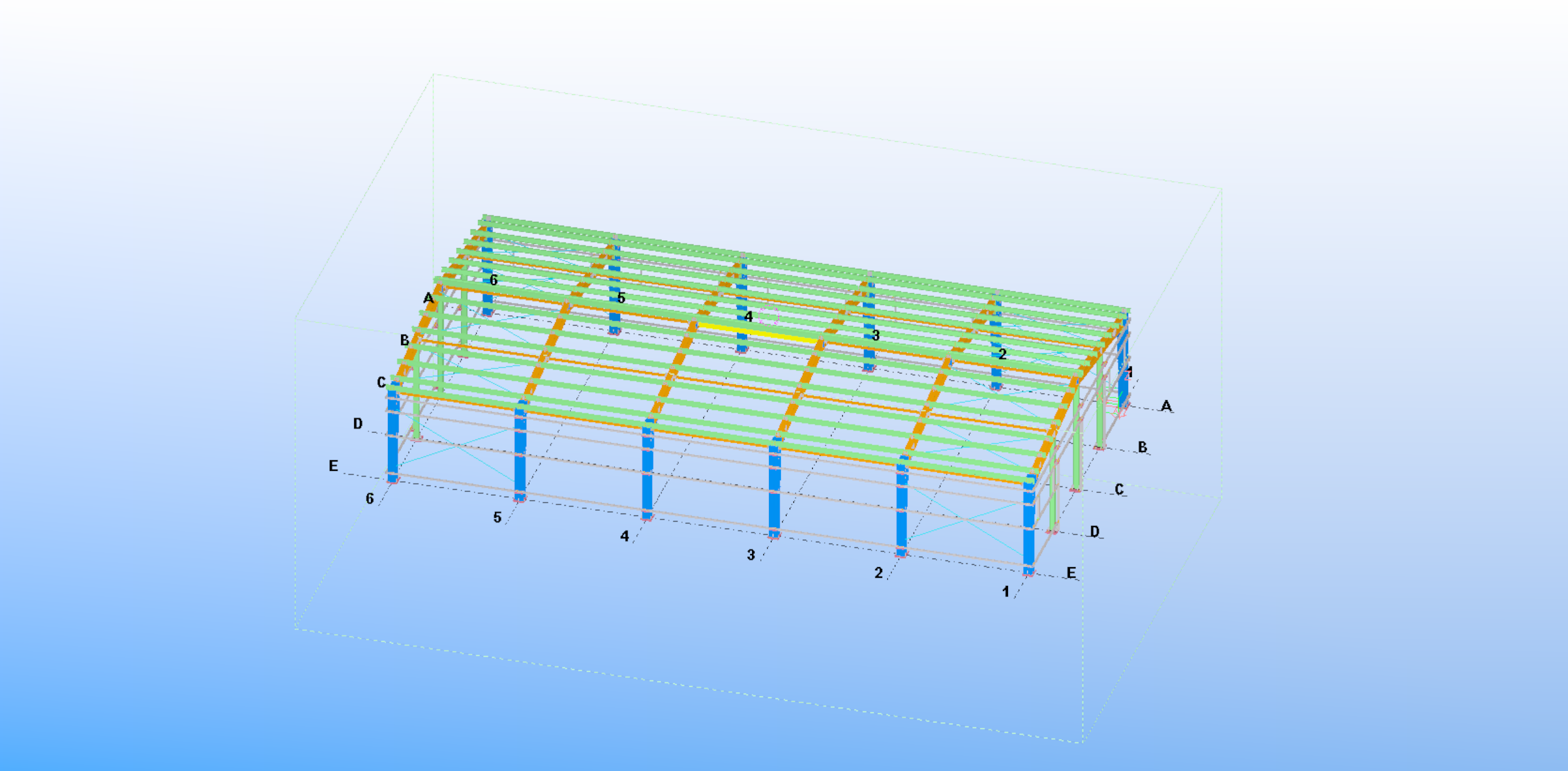

Another important aspect of the circular economy in the steel industry is the design of products for longevity and recyclability. By designing products with disassembly and recycling in mind, manufacturers can make it easier to recover and reuse materials at the end of a product’s life cycle. This approach, known as “design for disassembly,” can help to extend the lifespan of steel products and reduce the amount of waste generated during their disposal.

Furthermore, the steel industry is also exploring new business models that promote the sharing and leasing of steel products, rather than outright ownership. By shifting towards a more service-oriented approach, steel producers can retain ownership of their products and materials, allowing them to be reused and recycled multiple times. This can help to create a more sustainable and circular supply chain, while also fostering closer relationships with customers and suppliers.

Overall, the adoption of circular economy practices in the steel industry represents a significant opportunity to reduce waste, conserve resources, and minimize environmental impacts. By embracing recycling and reuse, designing products for longevity and recyclability, and exploring new business models, steel producers can help to create a more sustainable and resilient industry for the future. As the demand for steel continues to grow, it is essential that the industry continues to innovate and evolve towards a more circular and sustainable model of production.

Implementing Closed-Loop Systems in Steel Manufacturing for Environmental Benefits

The steel industry is one of the largest contributors to global greenhouse gas emissions and resource depletion. As the demand for steel continues to rise, it is crucial for the industry to adopt more sustainable practices to minimize its environmental impact. One such practice that is gaining traction in the steel industry is the implementation of closed-loop systems, also known as circular economy practices.

Closed-loop systems in steel manufacturing involve the recycling and reuse of materials throughout the production process. This approach aims to minimize waste generation, reduce the consumption of raw materials, and lower energy consumption. By closing the loop on materials, the steel industry can significantly decrease its environmental footprint and contribute to a more sustainable future.

One of the key components of implementing closed-loop systems in steel manufacturing is the recycling of scrap steel. Steel is one of the most recycled materials in the world, with a recycling rate of around 85%. By recycling scrap steel, the industry can reduce the need for virgin iron ore and coal, which are used in the production of new steel. This not only conserves natural resources but also reduces the energy required to extract and process raw materials.

In addition to recycling scrap steel, closed-loop systems in steel manufacturing also involve the reuse of by-products and waste materials. For example, slag, a by-product of steel production, can be used as a raw material in cement production or as a construction aggregate. By finding new uses for these materials, the industry can reduce the amount of waste sent to landfills and minimize its environmental impact.

Another important aspect of implementing closed-loop systems in steel manufacturing is the design of products for recyclability. By designing products with disassembly and recycling in mind, manufacturers can make it easier to recover and reuse materials at the end of a product’s life cycle. This approach not only reduces waste but also promotes a more circular economy where materials are continuously reused and recycled.

Transitioning to closed-loop systems in steel manufacturing requires collaboration and innovation across the entire supply chain. Steel producers must work closely with suppliers, customers, and other stakeholders to develop new processes and technologies that support a circular economy. This may involve investing in new recycling infrastructure, developing new recycling technologies, and educating employees and customers about the benefits of closed-loop systems.

Despite the challenges and complexities involved in implementing closed-loop systems in steel manufacturing, the benefits are clear. By adopting more sustainable practices, the industry can reduce its environmental impact, conserve natural resources, and create a more resilient and efficient supply chain. As the demand for steel continues to grow, it is essential for the industry to embrace circular economy practices to ensure a sustainable future for generations to come.