Earthquake-resistant ground crack design of steel structure

Table of Contents

Seismic Retrofitting Techniques for Steel Structures

Earthquakes are a natural disaster that can cause significant damage to buildings and infrastructure. In order to mitigate the impact of earthquakes on steel structures, engineers have developed various seismic retrofitting techniques. One such technique is the design of earthquake-resistant ground crack in steel structures.

When an earthquake occurs, the ground shakes and moves in a complex manner. This movement can cause the foundation of a building to crack, leading to structural damage. In order to prevent this from happening, engineers have developed a ground crack design that allows the building to move with the ground during an earthquake.

The ground crack design involves creating a series of joints in the foundation of the building that allow it to move independently of the ground. These joints are typically made of steel and are designed to flex and bend during an earthquake, absorbing the energy of the seismic waves and preventing damage to the structure.

One of the key advantages of the ground crack design is that it allows the building to remain standing even after a major earthquake. By allowing the building to move with the ground, the design reduces the stress on the structure and prevents it from collapsing. This can be particularly important in areas that are prone to earthquakes, where the risk of structural damage is high.

In addition to preventing structural damage, the ground crack design also helps to protect the occupants of the building. By allowing the building to move with the ground, the design reduces the risk of injury to those inside the structure. This can be crucial in the event of a major earthquake, where the safety of the occupants is of utmost importance.

The ground crack design is typically used in conjunction with other seismic retrofitting techniques to ensure the overall stability of the building. These techniques may include strengthening the steel frame of the structure, adding additional bracing or reinforcement, and improving the connections between structural elements.

Overall, the ground crack design is an effective way to make steel structures more earthquake-resistant. By allowing the building to move with the ground during an earthquake, the design helps to prevent structural damage and protect the occupants of the building. In areas that are prone to earthquakes, this technique can be crucial in ensuring the safety and stability of steel structures.

In conclusion, the ground crack design is an important seismic retrofitting technique for steel structures. By allowing the building to move with the ground during an earthquake, the design helps to prevent structural damage and protect the occupants of the building. Engineers continue to refine and improve this technique in order to make steel structures more resilient to earthquakes and other natural disasters.

Innovations in Earthquake-Resistant Steel Structure Design

Earthquakes are a natural disaster that can cause significant damage to buildings and infrastructure. In order to mitigate the impact of earthquakes, engineers and architects have been working on innovative designs for earthquake-resistant structures. One such design is the ground crack design of steel structures, which aims to improve the overall stability and safety of buildings during seismic events.

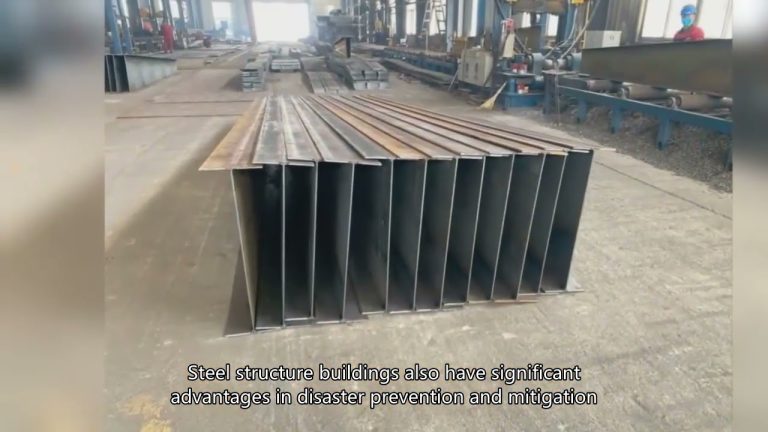

Steel structures are commonly used in construction due to their strength and durability. However, during an earthquake, these structures can be vulnerable to ground movement and shaking. The ground crack design of steel structures addresses this vulnerability by incorporating features that allow the building to absorb and dissipate the energy generated by an earthquake.

One key aspect of the ground crack design is the use of flexible joints and connections in the steel structure. These joints are designed to allow for movement and deformation during an earthquake, reducing the stress on the building and preventing structural failure. By allowing the building to flex and move with the ground, the risk of collapse is significantly reduced.

In addition to flexible joints, the ground crack design also includes the use of dampers and energy dissipation devices. These devices are installed throughout the structure to absorb and dissipate the energy generated by an earthquake, further reducing the impact on the building. By incorporating these devices, engineers can improve the overall resilience of the structure and enhance its ability to withstand seismic events.

Another important aspect of the ground crack design is the use of reinforced concrete foundations. These foundations are designed to provide additional support and stability to the steel structure, helping to prevent settlement and shifting during an earthquake. By strengthening the foundation, engineers can improve the overall performance of the building and reduce the risk of structural damage.

Overall, the ground crack design of steel structures represents a significant advancement in earthquake-resistant construction. By incorporating flexible joints, dampers, and reinforced foundations, engineers can improve the overall stability and safety of buildings during seismic events. This innovative design approach has the potential to save lives and reduce the economic impact of earthquakes on communities around the world.

In conclusion, the ground crack design of steel structures is a promising development in earthquake-resistant construction. By incorporating flexible joints, dampers, and reinforced foundations, engineers can improve the overall stability and safety of buildings during seismic events. This innovative design approach has the potential to revolutionize the way we build structures in earthquake-prone areas, ultimately saving lives and reducing the impact of natural disasters. As we continue to advance our understanding of seismic engineering, it is crucial that we embrace innovative designs like the ground crack design to create a more resilient built environment for future generations.